"POPUPGOOSENECKHITCH.COM IS NOT AFFILIATED WITH POPUP TOWING PRODUCTS, A SUBSIDIARY YOUNG'S WELDING INC. WE ARE HOWEVER, A FACTORY AUTHORIZED DEALER OF POPUP PRODUCTS"

About Hitches & Couplers Inc,

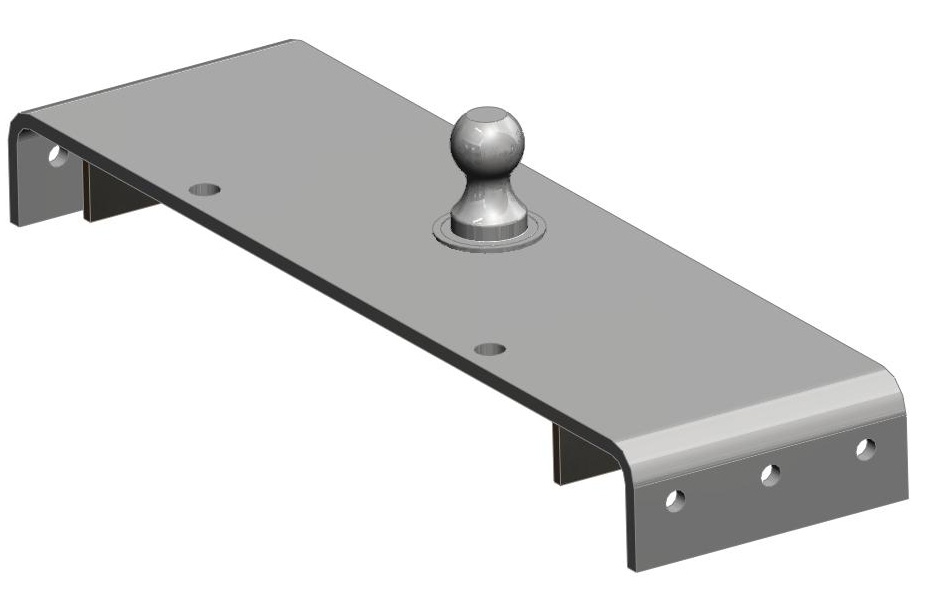

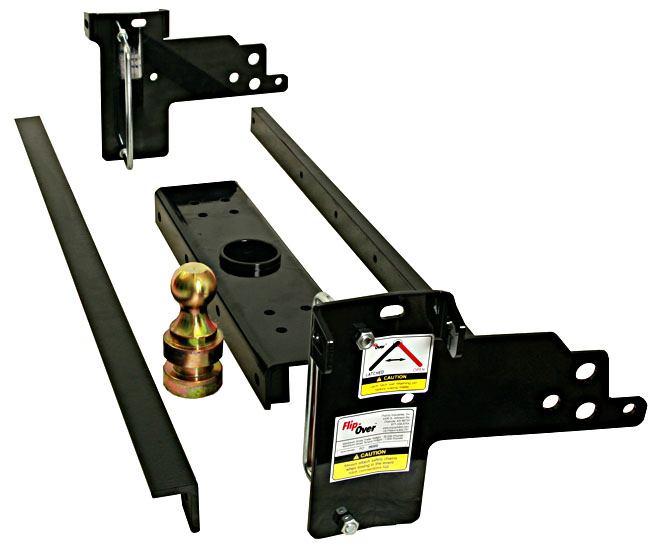

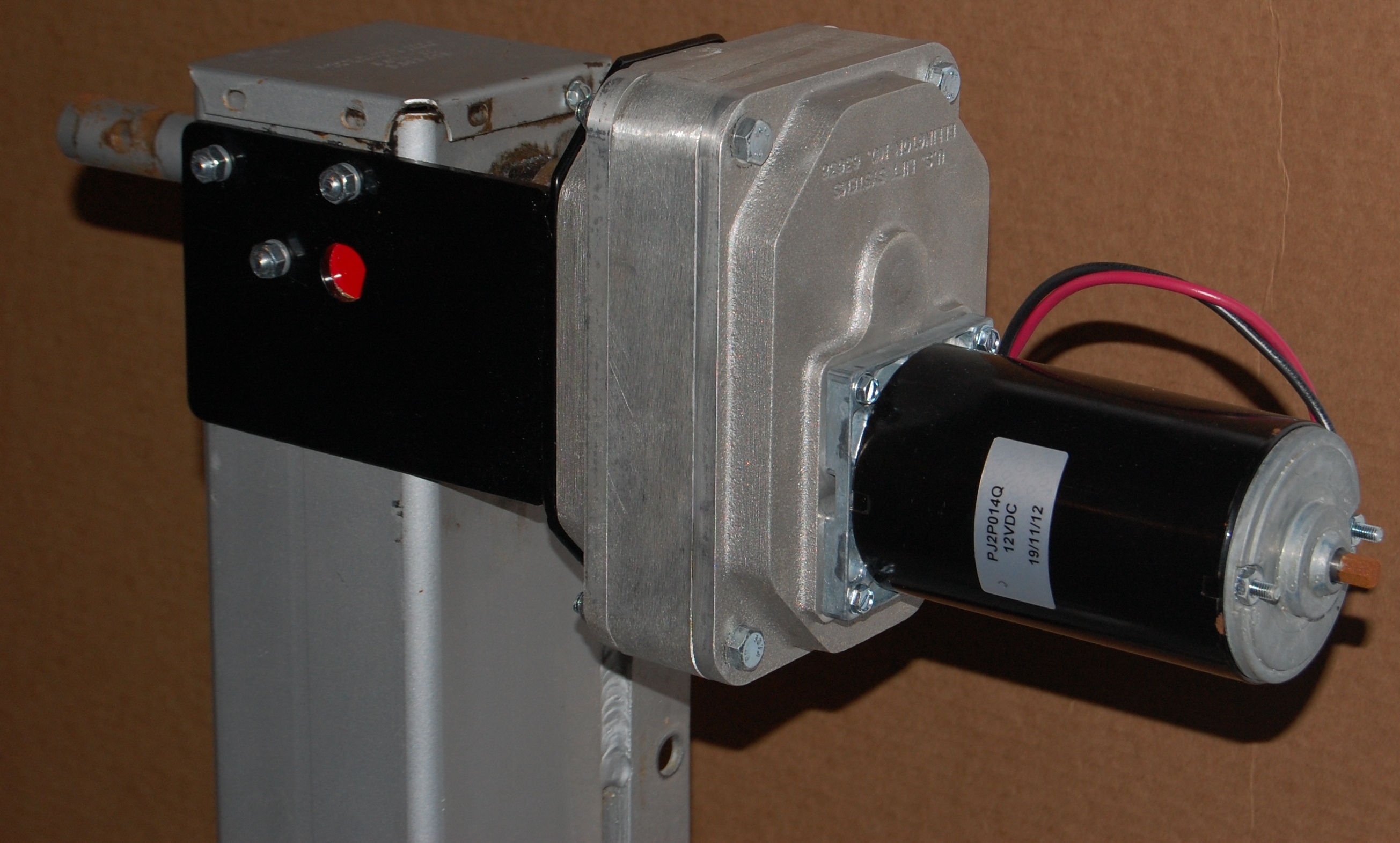

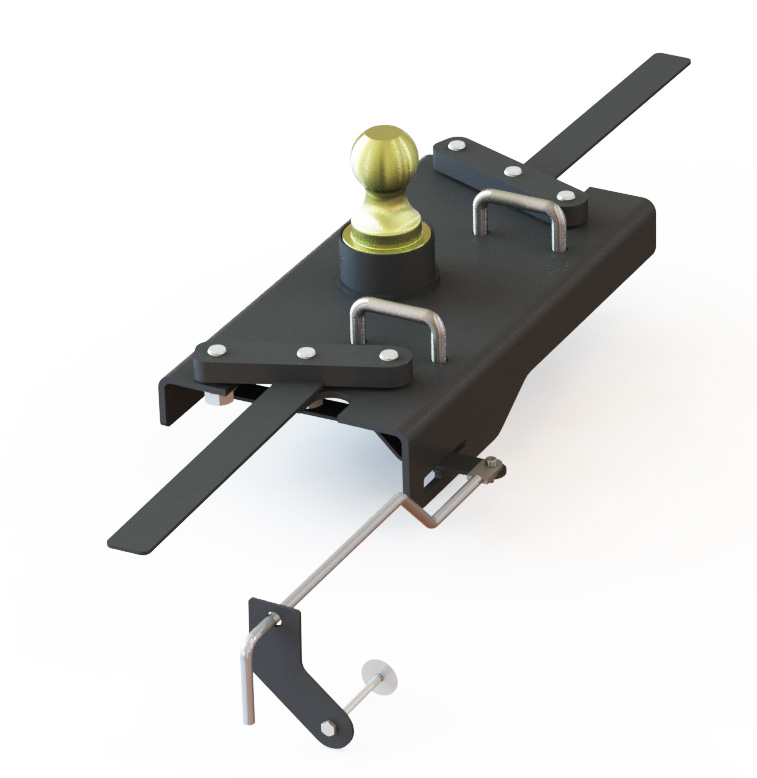

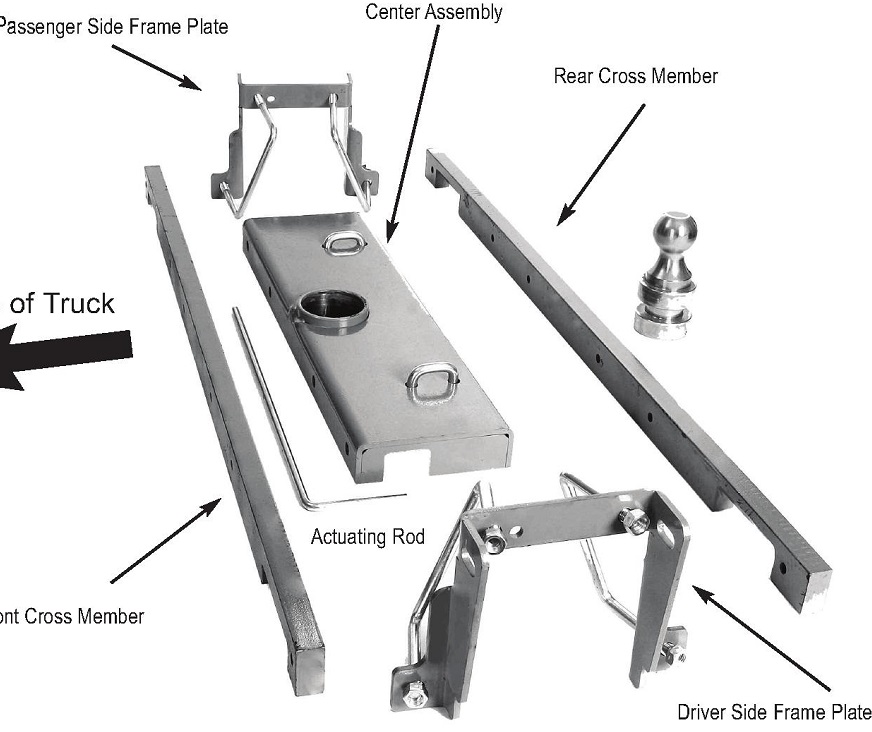

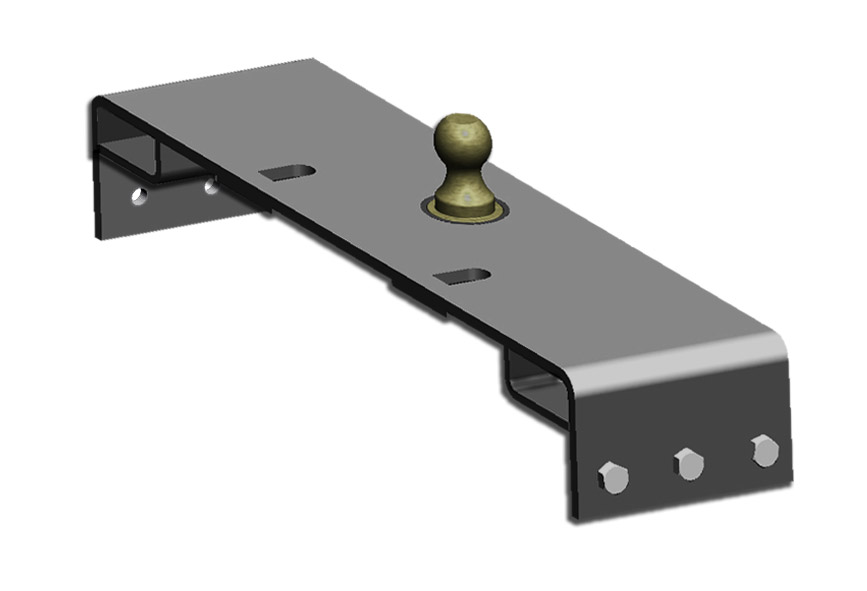

Hitches & Couplers Inc, sells gooseneck trailer and 5th wheel trailer towing products and gooseneck trailer jack landing gears plus electric converters for manual gooseneck trailer jacks.

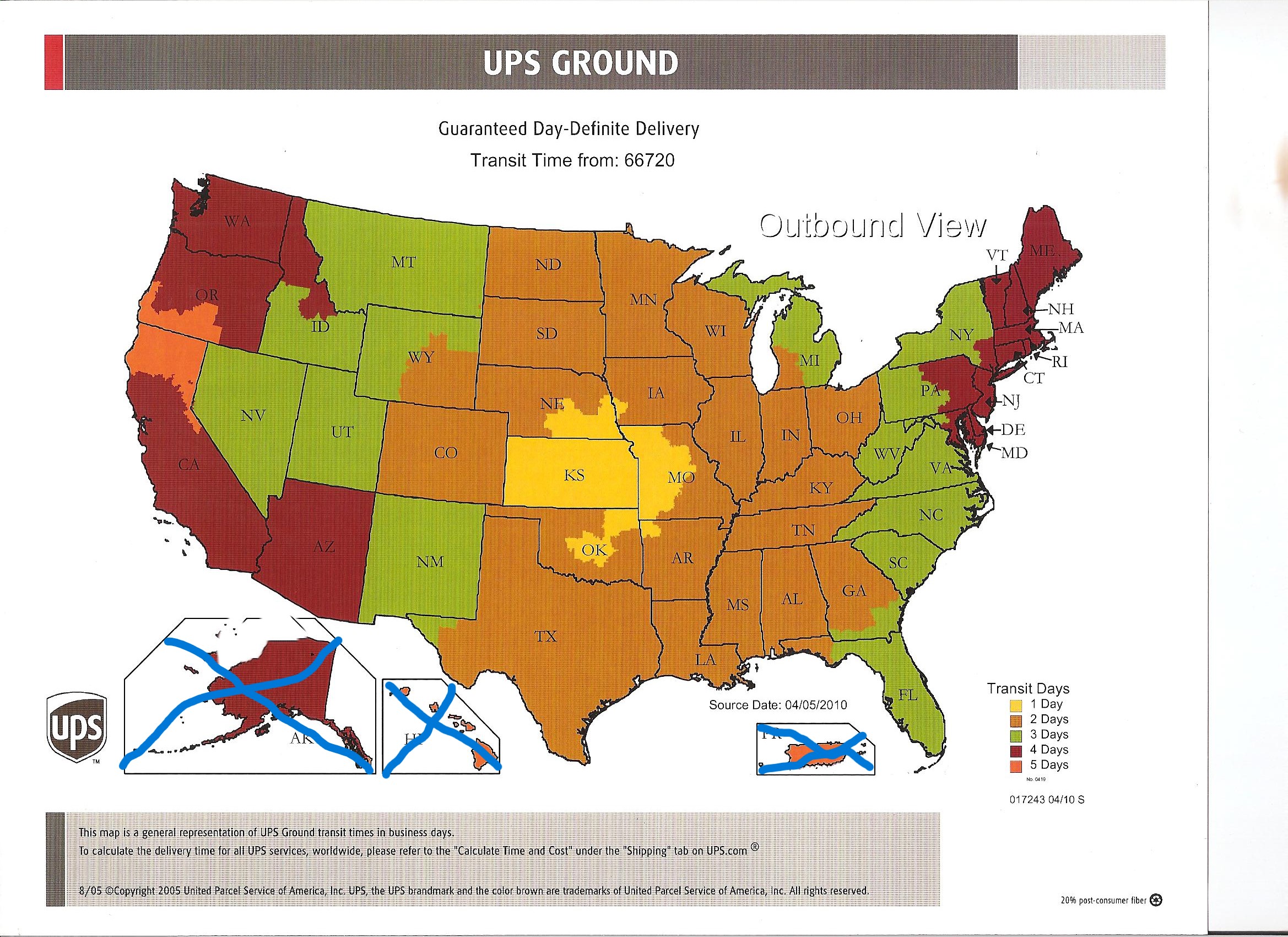

Hitches & Couplers, Inc. is a C-Corporation, incorporated April 4, 2006 as a privately held corporation, we are located in, and ship from the central United States. We are an authorized PopUp Towing Products and Magnum Lift dealer.

All products are new current models. We ship the same business day for orders received before noon Central Standard Time on a standard work day via UPS ground or FedEx. If by chance, you have ordered an item that is not in stock which is rare, we will email and/or phone you to let you know when it will be available and give you the option to keep it on order or to cancel and refund your money.